MIL-DTL-45859D

4.4.1 Material and design. Conformance to 3.2, 3.3, 3.3.1.1 thru 3.3.1.7, 3.5, and 3.7.3

thru 3.7.9, shall be determined by inspection of contractor records providing proof or certification

that materials conform to requirements. Applicable records shall include drawings, specifications,

design data, receiving inspection records, processing and quality control standards, vendor

catalogs and certifications, industry standards, test reports, and rating data.

4.4.2 Examinations. The test bench shall be examined for the following defects listed in

table I.

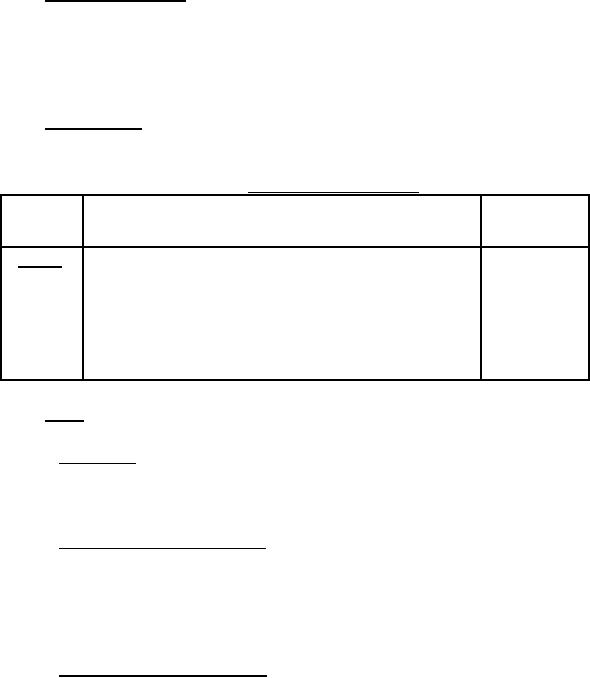

TABLE I. Classification of defects.

Method of

examination

Category

Defect

Major:

101

Safety shield not as specified (see 3.6).

Visual

102

Identification marking not as specified (see 3.8).

Visual

103

Instruction plates not as specified (see 3.9).

Visual

104

Treatment and painting not as specified (see 3.10).

Visual

105

Poor workmanship (see 3.11).

Visual

4.4.3 Tests.

4.4.3.1 Static load. Conformance to 3.3.1, place a uniformly distributed load of 1800 lb

on the top of the bench and 100 lb in each of the two drawers for 10 min. Any permanent

deformation, cracking, or breaking shall constitute failure of this test.

4.4.3.2 Low pressure pneumatic test. Conformance to 3.7.1, adjust the regulator to a

pressure of 10 psig and hold for 5 min. Then readjust the regulator to a pressure of 600 psig and

hold for 5 min. Finally readjust the regulator to a pressure of 1200 psig and hold for 5 min.

Leakage of the cylinder connection, filter, or regulator; or failure of the regulator to maintain the

set pressure within 1 percent for 5 min. shall constitute failure of this test.

4.4.3.3 High pressure pneumatic test. Conformance to 3.7.2, operate the three-way

cycling valve and precharge the amplifier receiver to 6000 psig. Attach the small test block to the

test connection and plug the test block. Slowly bleed the receiver pressure through the gage

manifold to the test block, observing the operation of the gage cutouts. Failure of the amplifier to

increase the source pressure of 6000 psi, malfunction of the gage cutouts, leakage or inability of

any component to withstand the applied pressure shall constitute failure of this test.

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business