MIL-PRF-83756D

which shall be irregular shapes and shall present cleaning problems typical to the application of this type

equipment. While blasting at 80 pounds per square inch gage on a flat surface, the machine shall produce a

cleaned path not less than one inch wide at the rate of one lineal foot in 10 seconds using size 13 glass beads and at

the rate of 4 lineal feet in 10 seconds using 26 grit aluminum oxide. In addition to the cleaning tasks performed,

Almen strips shall be peened to show compliance with Table I as specified.

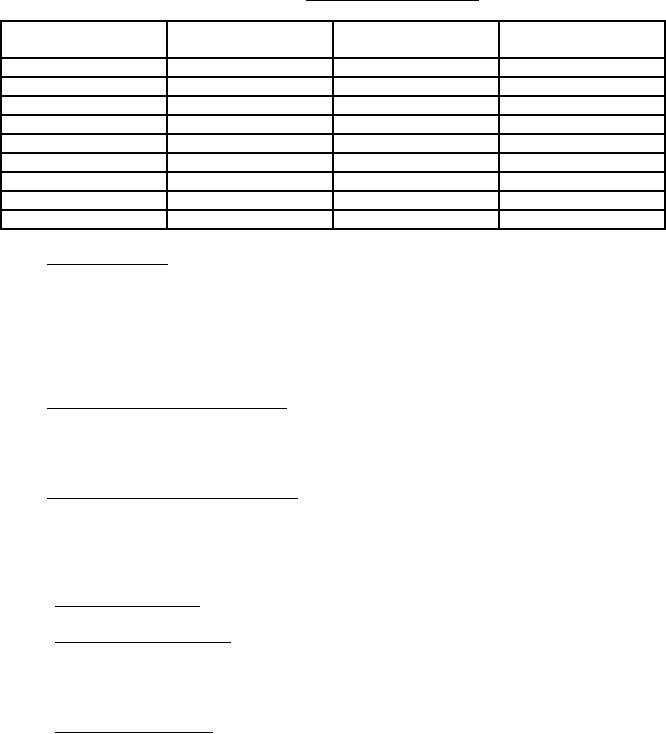

TABLE I. Performance Characteristics.

Air pressure at

Peen. Intensity

Bead Size

Regulator (psig)

Time (in seconds)

(min), (+.0005 A)

3

40

22

0.0060

3

60

22

0.0100

3

80

22

0.0140

8

40

22

0.0025

8

600

22

0.0040

8

80

22

0.0045

12

40

22

0.0015

12

60

22

0.0020

12

80

22

0.0025

4.4.7 Reclaim system test. The reclaim system test shall be performed using Size 8 glass beads as the blasting

media. The blasting media shall be sieved to insure a sieve analysis conforming to the limits set forth in SAE-

J444. A minimum of 5 pounds of the blasting media shall be cycled through the blast machine at least 10 times

while blasting at 80 pounds per square inch gage against a flat steel plate. The media will then be drained from

the machine and weighed, the weight being recorded. After weighing, the media will again be sieved and the

media retained on the sieve shall weight not less than 80 percent of the weight recorded above. Values less than 80

percent shall cause rejection of the machine.

4.4.8 Exhaust and dust collector test (Type I). During the 4-hour performance test of the Type I blast machine, the

exhaust and dust collector system shall be observed for proper operation. Certification shall be considered as

evidence that the exhaust system replaced the air within the cabinet at least 10 times per minute. However, a dust

free and leak proof system shall still be required and proven to exist.

4.4.9 Recovery and dust collector test (Type II). During the 4-hour performance test of the Type II blast machine,

the recovery and dust collector system shall be observed for proper operation. The contractor shall demonstrate the

recovery system to be 90 percent efficient. The blast gun brushes shall not allow escape of blast media to the

atmosphere. A dust free climate shall exist around the blast machine. The mechanical filter shaker shall be

operated and the dust-tray removed and emptied.

4.4.10 Work floor test (Type I). The work floor shall be loaded at the center with 500 pounds and the maximum

deflection measure. The deflection shall not exceed ¼ inch.

4.4.11 Lighting system test (Type I). Using a General Electric Type 213 light meter or equivalent, the light

intensity shall be checked at the work floor with the access door closed. The light meter shall be placed on the

center of the work floor and moved to each corner in turn. The minimum reading shall be 150 foot candles in each

corner and 200 foot candles at the center.

4.4.12 Individual acceptance test. Each production item blast machine shall be subjected to a one-hour

performance test using blasting media of size 13 glass beads for 30 minutes and 26 grit aluminum oxide for 30

minutes. During the test period, the blast machine shall perform cleaning tasks typical to the application of this

type equipment.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business